Impeller flow meter RIZUR-DOR

ТU 26.51.52-001-12189681-2018

Conformity certificate № EAЭС RU C-RU.HA91.B.00029/19

Cut-in design version of the impeller flow meter RIZUR-DOR is an ideal solution for the flow measurement of water or similar liquids in the pipelines of big diameters. The liquid flow, passing through the pipes, makes the impeller move. The speed of the impeller is proportional to the flow speed and subsequently, to the flow rate. Due to symmetrical construction, cut-in design variant of the impeller flow meter RIZUR-DOR can be used for bidirectional flow measurement.

The flow meter is cut in the pipeline and mounted using thread or pin end connection. Cut-in design version of the impeller flow meter RIZURDOR can be submerged to the exact depth point which allows performing high-precision measurements. Due to the cut-in design version, the flow meter is more efficient than full-bore flow meters. It's particularly apparent when comparing the prices of the flow meters for the big diameter pipelines.

Design description and functions In the impeller flow meters RIZUR-DOR the measured flow makes the impeller blades spin with the rotating speed that is proportional to the flow rate. The rotating speed is registered in a non-contact way through the wall of the frame. The speed of impeller is converted into a frequency of current pulses. Low weight of the impeller provides quick response (<50 ms). The housing of the impeller flow meters RIZUR-DOR is made of stainless steel 316L. The impeller is available in versions from PVDF or PEEK, with an auto-lubricating bearing made of graphite or PTFE which has a long service life. On request, the flow meter can be equipped with an indicator unit, adder, batch meter, etc.

Application areas

-

Heating, venting, air conditioning: hot and cold water, control of the heating and thermal systems

-

Communications: distribution, management, and purification of water

-

Irrigation: water management

-

Water management: chlorination, desalination, mechanical filtration, soil stabilization with the chemical injections

-

Petroleum refinery systems: media pumping, heating and cooling systems

-

Electricity generation: boiler feed water; steam condensate, power water, water balance

-

Chemical agents: power water, water in cooling towers, chemical dosing, water dosing

-

Other: cement production, diesel fuel transportation, fluidity test, flow control in fire engines and hydrants, food industry, paper production, mining operations.

Installation in hot pipelines for Rizur-DOR-5

Standard installation

Direct pipe installation requirements

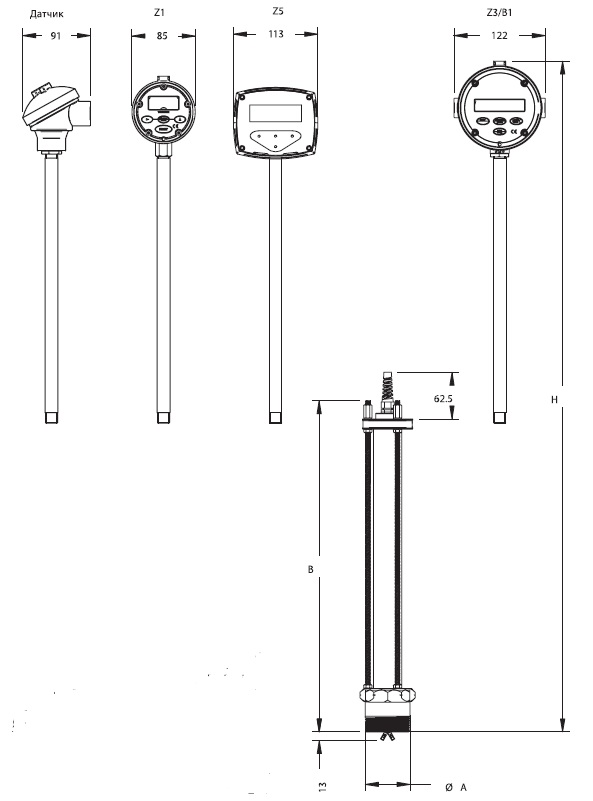

Dimensions, mm

| Measuring range, l/h | from 0,25 ... 6 300 to 0,4 ... 49 000 |

| Flow rate, m/s | 0,3 ... 10 |

| Nominal pressure, bar | up to 80 |

| Medium viscosity | low |

| Process temperature, °С | up to +200 |

| Accuracy, % | ± 1,5 with steady flow |

| Output signal | LCD-display; batch meter; adder; impulse; analogue 4-20mA; HART; other (on request) |

| Material | Stainless steel |

| Process connection | R 11/2, R 2 male thread, 11/2" NPT, 2" NPT male thread for tubes with a diameter: from DN 40 to DN 2500 |

| Ambient temperature, °С | -40 ...+60 (-70 ... +60 with a soft enclosure) |

| Power supply | Without power supply; 8-24 V DC; Batteries |

In accordance with the metrological requirements, impeller flow meter RIZUR-DOR is a device for technical control.

Operating temperature limits for the impeller and the output (options)*

| Impeller | Max. t. of the measured media |

| PVDF | 100 °С |

| PEEK | 200 °С |

| Output/sensor type | |

|

F1-F6 R1-R5 Q1-Q4 |

125 °С |

| N5,Q5 | 150 °С |

| Е1-Е4 | 85 °С |

| T5,R6 | 125 °С |

| Н5 | 200 °С |

Dimensions, mm, ± 2 mm

| RIZUR-DOR-42 | RIZUR-DOR-52 | |

| ØA | 1 ½"or 2" NPT/R2 | 2" NPT/R2 |

| В | 198 | 444 |

| Configuration | H | H |

| Sensor | 385 | 869 |

| Z1 | 394 | 880 |

| Z3/B1 | 415 | 900 |

| Z5 | 380 | 865 |