Gauze filter

Many types of pipeline equipment such as pressure control valves, indicators, pumps – are extremely sensitive to the purity of the operating medium and can’t have any extraneous mechanical particles. In order to ensure equipment protection, there’re gauze filters installed that retain all of the particles bigger than the holes of the gauze element.

Gauze filters are designed for the filtration and clearance of different operating media both liquid and gas: water, oil, natural gas, and other mechanical particles and foreign bodies.

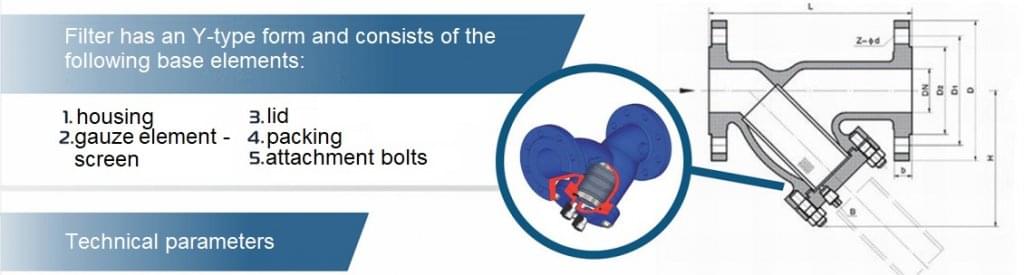

Gauze element in the filter is a screen with holes that influence the degree of purification. It’s necessary to clean the filter from the accumulated foreign bodies on a regular basis. As a rule, the filter is dismountable and the gauze element is replaceable.

The filter housing can be made out of different materials: cast-iron, carbon steel, stainless steel. In the production plants filters with flange connection are used. The flanges are manufactured acc. to GOST 12815-80, the possible design variants are from 1 to 9. In most cases the filters are manufactured in the 1 design variants (non-aggressive operating medium – water, vapour; operating pressure – up to 16kgs/cm2). For more aggressive media at the petroleum or chemical production facilities with operating pressure 25-40 kgs/cm2 filters with flanges of 2, 3, 4, 5 are used.

Gauze filters are mounted onto horizontal or vertical pipeline. The flow direction must be the same as indicated with an arrow on the housing. For vertical mounting the flow should be top-bottom.

Operating principle

The gauze element – a screen – retains all the mechanical pollution (dirt, rust, cutting waste, etc.) of the passing operating medium. In order to clean the filter, it’s necessary to take the lid off, take out the gauze element and remove all the pollutants. For cleaning the filter without depressurization in the pipeline, it’s possible to install a plug in the lid of the ball valve.

Operating media

- Non- aggressive: air, water, vapour, light-end products and hydrocarbon fuels

- Aggressive: acids, alkalies, petroleum, petroleum products, natural gas

Application

Most widely applied are the filters with a housing made of carbon steel and a screen made out of stainless steel.

Housing material – carbon steel.

This type of filters is designed for the mechanical cleaning of large amounts of media on an industrial scale, including media with temperatures up to 300 degrees (water, vapour, neutral liquids, gases). The degree of cleaning depends on the technical requirements on filtration while taking into account requirements on the pressure difference (operating media pressure).

Steel gauze filters are used for cleaning water, vapour, and other non- aggressive media in different spheres of the industry and community facilities.

Stainless steel gauze filters

Most widely filters used for aggressive media are the gauze ones with housing and screen made of stainless steel.

Housing material - AISI 304/316/316L

Stainless steel filters have a wider range of working temperatures, can operate under higher pressure, and can be used for lots of different processing media non-aggressive to the materials of the filter.

Filters made of the stainless steel are used at the stainless and plastic pipelines, primarily in cases when there’re no black pipes.

Application

- waste water filtration;

- acid and alkaline production;

- petrochemical industry;

- chemical industry;

- paper making industry;

- food industry;

- condensate circuits