Explosion-proof inductive heater RIZUR-VIN

Application area

Explosion-proof inductive heater RIZUR-VIN is used in the hazardous areas in the indoor and outdoor facilities in accordance with the explosion protection marking acc. to GOST 30852.13-2002, Regulations of equipment installation (PUE), Ch.7.3, and other regulatory documents concerning the usage of the electric equipment in the hazardous areas.

Design description

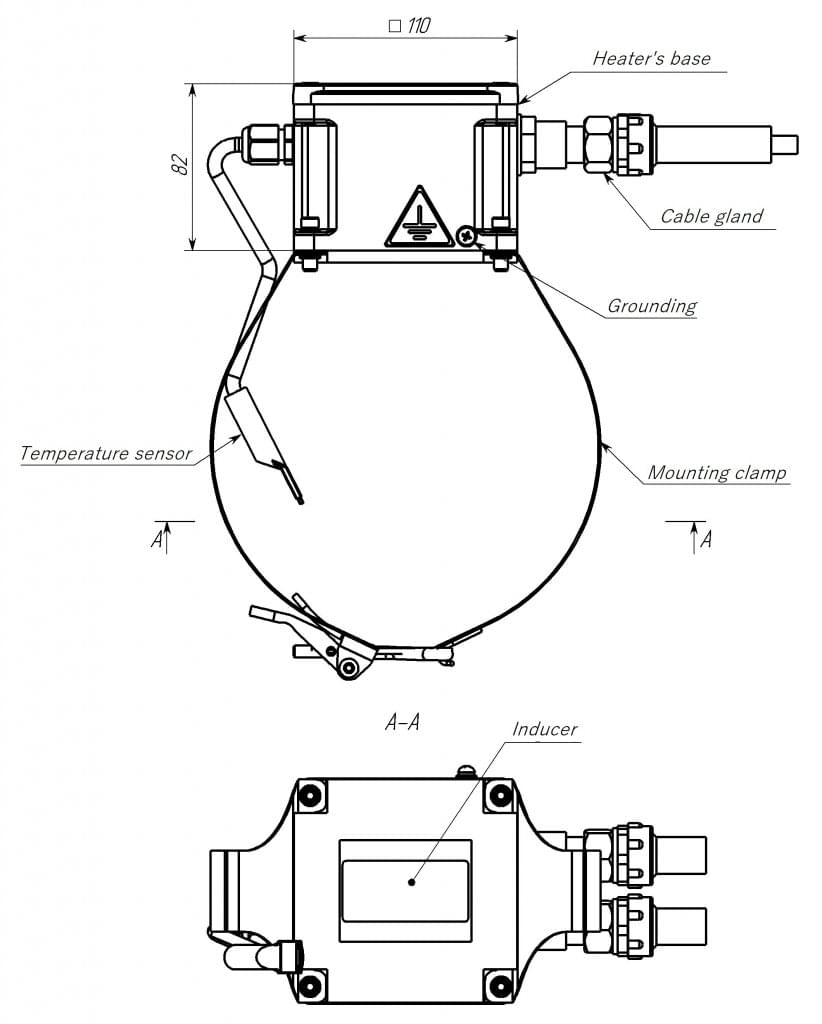

Structurally, RIZUR-VIN consists of a processing module, a resonant converter module, and an external temperature sensor. Due to the complexity of implementing sustainable resonance in the converter, latest developments and lots of protective functions (overvoltage, current, excessive temperatures, resonance change connected with the change in the housing parameters) are used.

Operation algorithm

After power supply connection, there's a first initialization of the process module and the light-emitting diode is blinking green. Then there's a functional check of all the sensors.

If any of the temperature sensors are broken (quintuple check of the sensor's responses) then the indicator signalizes emergency mode, signaling that the relay is activated and the indicator has an error code displayed.

If all the sensors passed the tests then the main algorithm for the heating control is activated. Each cycle of the temperature testing (about 1 sec) has a sensors check.

If there's a current overload then an inbuilt protection is activated, which turns off the inductor, the

indicator signalizes emergency mode and the light-emitting diode is red. Error reset (hester's reboot) is done with putting a magnet close to the housing of the enclosure (10 mm lower than the light-emitting diode).

If any of the temperature sensors are broken (quintuple check of the sensor's responses) then the indicator signalizes emergency mode, signaling that the relay is activated and the indicator has an error code displayed.

If all the sensors passed the tests then the main algorithm for the heating control is activated. Each cycle of the temperature testing (about 1 sec) has a sensors check.

If there's a current overload then an inbuilt protection is activated, which turns off the inductor, the

indicator signalizes emergency mode and the light-emitting diode is red. Error reset (hester's reboot) is done with putting a magnet close to the housing of the enclosure (10 mm lower than the light-emitting diode).

Explosion protection

As required by the explosion protection regulations, the heater's design complies with GOST 30852.0-2002 and GOST 30852.17-2002 as electric equipment of high Ex-protection, with «compound encapsulation (m)».

All the heater's electric elements have a metal coating with the wall thickness of at least 2 mm. In accordance with the GOST requirements, all the current-conducting elements inside the housing are sealed with a joint compound. Electrical insulation should withstand dielectric strength tests for 1 minute with the testing voltage at no more than 500V (AC current, 50 Hz) without breakdown and surface discharge.

The heater has inside and outside grounding in accordance with the GOST 22782.3-77. Cable connection is done through the clamping device that prevents its pull-out.All the heater's electric elements have a metal coating with the wall thickness of at least 2 mm. In accordance with the GOST requirements, all the current-conducting elements inside the housing are sealed with a joint compound. Electrical insulation should withstand dielectric strength tests for 1 minute with the testing voltage at no more than 500V (AC current, 50 Hz) without breakdown and surface discharge.

Risk and safety statements

The heater is an explosion-proof equipment. It is a class I type of equipment according to GOST R

12.2.007.0-75 in regard to protection against electric shock. Before putting into operation, it's necessary to check the state of health of the housing and the reliability of connection to the local grounding circuit. The mounting and connection of the heater should be carried out by the trained staff that has a right for performance of work according to the requirements. The current should be cut off.

12.2.007.0-75 in regard to protection against electric shock. Before putting into operation, it's necessary to check the state of health of the housing and the reliability of connection to the local grounding circuit. The mounting and connection of the heater should be carried out by the trained staff that has a right for performance of work according to the requirements. The current should be cut off.

Operating and technical maintenance

The heater does not require maintenance or servicing.

It's recommended to check the following before the heating season:

- Electrical Installations Code (PUE);

- Chapters 3.4 of "Operational code for electrical installations" (PEEP) and Safety regulations - «Electrical installation in hazardous areas»;

- Instruction BCH332-74/MMCC (“Instructions for installation of electrical equipment, power and lighting lines in hazardous areas”) ;

- State of health of the installed heater (presence of heating);

- Make sure that there're no mechanical defects;

- Clean the surface from the dust.

Technical specifications

| Supply voltage, V | 230 |

| Nominal power, W | 150 |

| Maximum power, W | 220 |

| Operation temperature | -60°С ... +40°С |

| Ingress protection | IP66 |

| Certificate TR ТS 012: № ТС RU С-RU.МЕ92.В.00946 | |