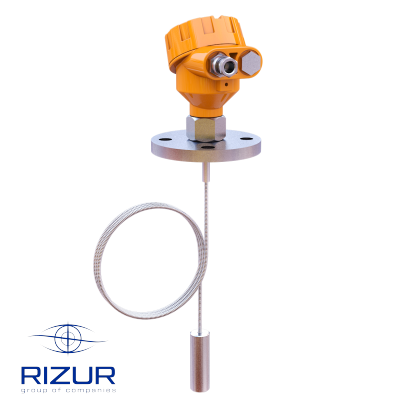

Guided radar level transmitter RIZUR-1300

Guided radar level transmitter RIZUR-1300 is designed for the level control in open and closed, including those under pressure, reservoirs in the process units of industrial objects of chemical, petrochemical, oil-refining, metal, heat&power, and many other branches of the industry. It can also be used to indicate the presence/absence of liquid at a previously set height.

Technical regulations TU 26.51.52-001-12189681-2018

Conformity certificate of the Customs Union EAEU RU C-RU.HA91.B.00029/19

Intended use

RIZUR-1300 is a guided radar level transmitter with a wide range of applications in chemical, metallurgical, and all the branches of fuel industry: petroleum, gas, electric power, coal, peat.

Guided radar level transmitter uses the technology of impulse reflectometry. Electric impulses, generated by the equipment, spread through the probe reaching the interface level and reflect back to the circuitry which then calculates the medium level from the time difference between the impulses sent and the impulses reflected.

The sensor can output the data as a 4...20mA analogue signal as well as a discrete signal upon reaching the set level. Using data recording module, one can read, modify, store and analyze all the process parameters from anywhere, at any time through a web-browser.

Guided radar level transmitter is the best choice for highly reliable level measurement and a great alternative for the traditional measuring principles such as ultrasonic, capacitive, conductive, displacer, float and hydrostatic.

Guided radar level transmitter doesn't depend on the changing of process conditions, such as density, viscosity, conductivity, temperature, pressure, dielectric capacitivity, etc.

Application area

The transmitter stably operates in almost all liquids and solids regardless of the changes in the measured medium parameters, such as density, conductivity, temperature and pressure. Adverse conditions, such as turbulence or vapour, do not affect the accuracy or reliability of the transmitter.

RIZUR-1300 is applicable in all types of processes and has stable characteristics in media with low dielectric constant, such as oils and hydrocarbons.

Guided radar level transmitter has few limitations in mounting, it can be mounted in small tanks, tall and narrow nozzles. Complex construction or presence of protrusions inside the vessel in close proximity to the transmitter do not affect the accuracy or reliability of the transmitter.

Guided radar level transmitter RIZUR-1300 is certified in accordance with GOST R MEK 60079-0-2011 and can be used in explosive areas.

Probe types

The wire rope probe is recommended for both solid and liquid media, including those in tall tanks and places with limited space for installation. The coaxial probe is not susceptible to any external conditions and objects outside its tube which would otherwise cause disturbances in the signal. This construction makes the coaxial probe the ideal solution for reliable measurement under almost any operational conditions.

An extended temperature option, -195°C to +250°C, is available on request for the single rod and coaxial probe. For chemically aggressive and corrosive media there's also a single rod probe made of chemically-resistant materials available on request.

Installation

Guided radar level transmitter can be supplied with different types of process connection - thread, sleeve nut, flanges (made acc. to Russian and international standards). Minimal thread size is М27х1,5 or G¾". Guided radar level transmitter RIZUR-1300 can be mounted directly on the vessel as well as on a bypass pipe. Due to the possibility of manufacturing the products with different types of process connection, RIZUR-1300 can be mounted onto any existing technological connection without any changes introduced. Mounting and debugging of RIZUR-1300 does not require any additional knowledge or skills from the personnel.Electric installation

Probe types

|

|

Rod probe | Wire rope probe | Coaxial probe |

|

Probe material |

Stainless steel 12х18н10т / AISI 321 |

Stainless steel 12х18н10т / AISI 321 |

Stainless steel 12х18н10т / AISI 321 |

|

Probe length, mm |

500 ... 3 000 | 2 500 ... 20 000 | 500 ... 6 000 |

|

Top inactive area,mm |

80 | 80 | 50 |

|

Bottom inactive area,mm |

50 | 50 | 50 |

|

Max. probe load |

6 Nm (lateral load) |

5 kN (tensile load) |

100 Nm (lateral load) |

|

Probe diameter, mm |

6 | 4; counterweight 22 | 20 |

|

Ambient temperature, °C |

−40... +85 −70... +85 (with an enclosure or a soft enclosure) |

−40... +85 −70... +85 (with an enclosure or a soft enclosure) |

−40... +85 −70... +85 (with an enclosure or a soft enclosure) |

|

Process temperature, °C |

−196 ... +250 | −196 ... +250 | −196 ... +250 |

Technical specifications

| Housing material |

Aluminum alloy; Stainless steel |

| O-ring sealing | Rubber; Silicone |

| Explosion protection marking | 0ExiaIICT6X; 1ExdIICT6; without explosion protection |

| Ingress protection | IP67/IP68 |

| Output signal |

4-20mA, analogue, 4-wire system; Digital output (in acc. with the settings) open collector PNP |

| Accuracy | 0,03% of the measured value, but at least 3 mm |

| Repeatability | < 2 mm |

| Response time | < 100 ms |

| Supply voltage | 12... 30 V DC |

| Current consumption | < 50 mA at 24 V |