Gas skids RIZUR-GM

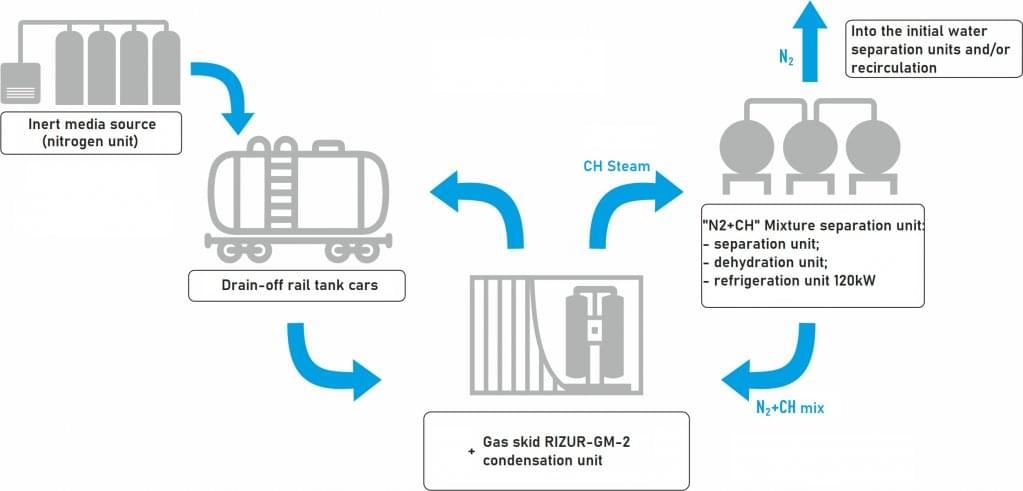

- the decrease of the in-process loss

- the decrease in electrci power and nitrogen gas consumption

- condensation of the compressed vapor phase of the product

- separation of the «N2+CH» mixture

NPO RIZUR has developed a fundamentally new resource-saving technology and equipment, which allows to produce gas drainage and full selection (disposal of residues) of LPG during the drainage operations.

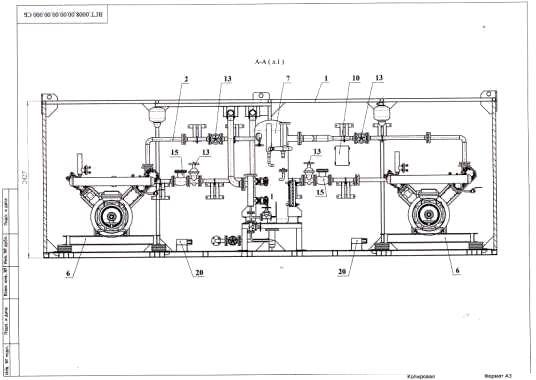

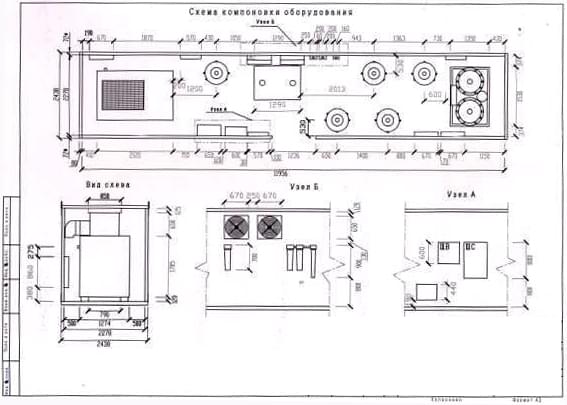

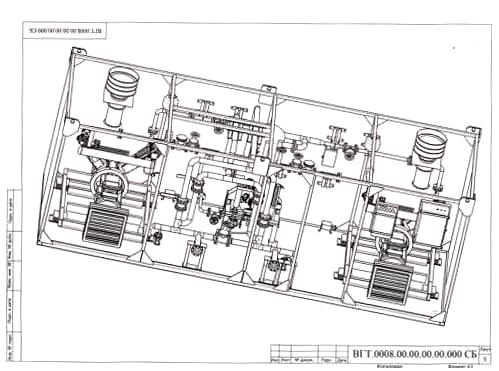

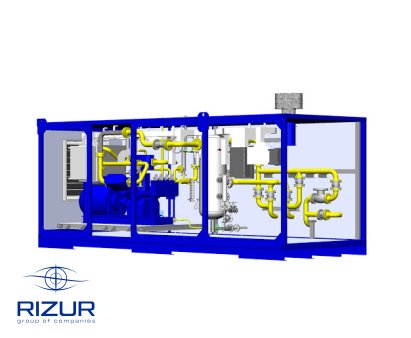

We offer to implement unified technological gas modules (RIZUR-GM1, RIZUR-GM2, RIZUR-GM3) with a complete technological cycle, block-container and mobile version, designed for carrying out drainage and filling operations in the technological projects of gas filling stations, gas stations, BSG, gas reception and storage terminals, LPG production plants, as well as nitrogen stations of block-container type, designed to produce gaseous nitrogen from atmospheric air directly at the place of operation, used for degassing (neutralization) of tank wagons carrying LPG.

Advantages of using mobile modules of RIZUR-GM type:

1. Draining and loading operations with any tanks for LPG transportation and storage without technological losses of the drained product.

2. Complete selection (disposal) of the remaining commercial products.

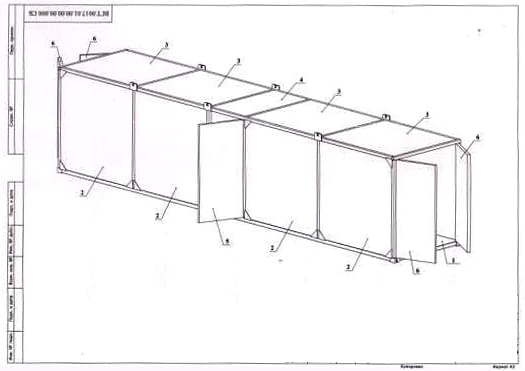

3. High mobility - RIZUR-GM module is manufactured in block-container and mobile version on the truck chassis.

4. Minimal volume of installation and commissioning works - at creation of modules "plug & play" principle is used.

5. Compliance with industrial and environmental safety requirements.

6. Airtightness and closeness of the technological system of product pumping.

7. Degassing (neutralization) of tank wagons and containers for the purpose of preparation for filling, ADHD, when changing the product.

New developed technology of separation of "N2+CH" mixture for reducing nitrogen losses during the discharge of tank wagons in winter period of operation.

| Parameter | Measur. | UTMG-01* | UTMG-02* | UTMG-03* | UTMG-01М1 | UTMG-02М | UTMG-03М* | UTMG-01М2 | |||

| units | |||||||||||

| Compressed media | - | Propane, butane and their mixtures acc. to GOST 20448-90, GOST 27578-87 | |||||||||

| with an admixture of 4-6% by volume: methane, ethane, ethylene). | |||||||||||

| Primary pressure, absolute | Min | MPa | 0,15 | 0,15 | 0,1(0,15) | 0,13 | 0,05 | 0,1 (0,15) | 0,13 | ||

| Max | 1,1 | 1,1 | 0,35 | 1,7 | 1,6 | 0,35 | 1,7 | ||||

| Final pressure, absolute | Min | 1,1 | 1,1 | 1,7 | 1,7 | 1,8 | 1,7 | ||||

| Max | 1,7 | 1,7 | 1,7 | 1,7 | 1,8 | 1,7 | 1,7 | ||||

| Gas temperature at the entrance | Min | С° | -40 | -40 | -40 | -45 | -45 | -40 | -45 | ||

| 45 | 45 | 45 | 45 | 45 | 45 | 45 | |||||

| Max | |||||||||||

| Final temperature, under | 125 | 125 | 125 |

+15…+25 to ambient air temperature |

125 | 150 | |||||

| 125 | |||||||||||

| Volumetric capacity reduced to initial suction conditions | m³/sec | 0,008(0,5) | 0,07(4,2) | 0,05(3,0) | 0,014 (0,83) | 0,08 (5,0) | 0,05 (3,0) | 0,014х2 (0,83)х2) | |||

| (m³/min) | |||||||||||

| Installed power on the shaft, under | kW | 15,0(11,0) | 55 | 55 | 16 | 132 | 55 | 22,0 х 2 | |||

| -75 | |||||||||||

| Rated shaft speed (deviation ± 2%) | С‾¹ | 10,85 | 12,25 | 12,25 | 12,3 | 12,25 | 12,3 | ||||

| Number of compression stages | - | 2 | 2 | 3 | 2 | 2 | 3 | 2 | |||

| Compressor drive | - | Explosion-proof asynchronous electric motor with IЕxd11ВТ4 | |||||||||

| ВА160М6У2 | 2В280S8У2,5** | AIMUR 280S6 | 2В280М8У22,5 | ||||||||

| TU 16-510.812-83 | TU 16-510.812.-83 | ||||||||||

| Rated drive power | kW | 18,5 | 55 | 55 | 22 | 75 | 75 | 22 | |||

| Missing hours, over | hours | 1000 | 1000 | 1000 | 2000 | 2000 | 1000 | 2000 | |||

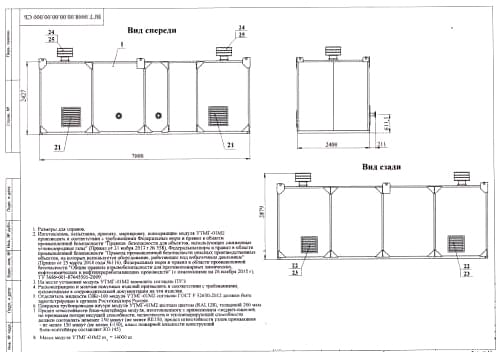

| Module dimensions, under | Length | m | 4 | 6 | 4 | 6,6 | 6,12 | 7 | |||

| Width | 2,45 | .2,4 | 2,6 | 2,5 | 2,4 | ||||||

| Height | 2,45 | 2,45 | 2,45 | 2,5 | 2,45 | ||||||

| The weight of the module, under | kg | 2500 | 7000 | 8000 | 3000 | 14000 | 8000 | 6000 | |||