Relay sensor RIZUR-300

RIZUR-300 is a multi-functional conductometric relay sensor that is a new achievement in the field of control and measuring equipment.

Unlike other analogue conductometric relay sensors, RIZUR-300 has an explosion-proof and an intrinsically safe design variants and so can be used in hazardous areas on the inside facilities and processing systems.

- general purpose industrial grade explosion-proof variant with 1ExibIIBT4 marking

- for operating in hazardous areas

Design description and functions

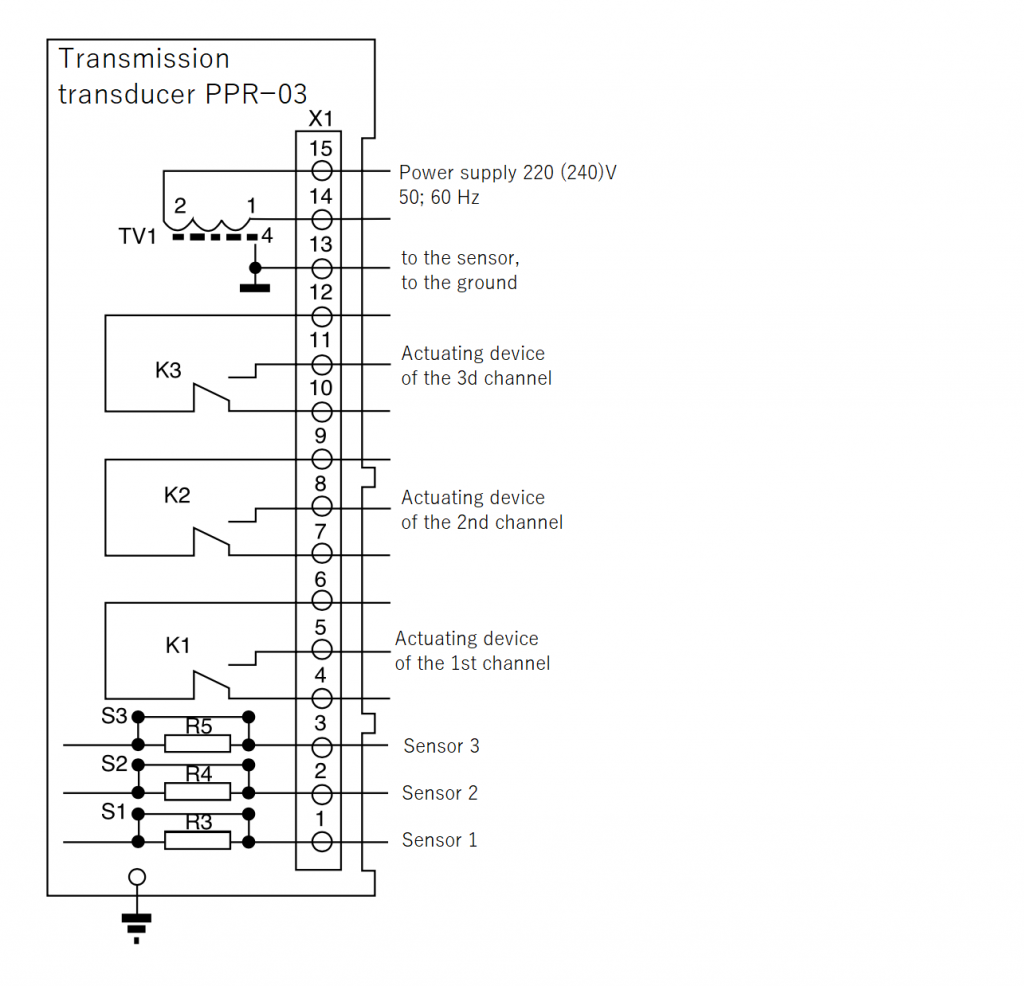

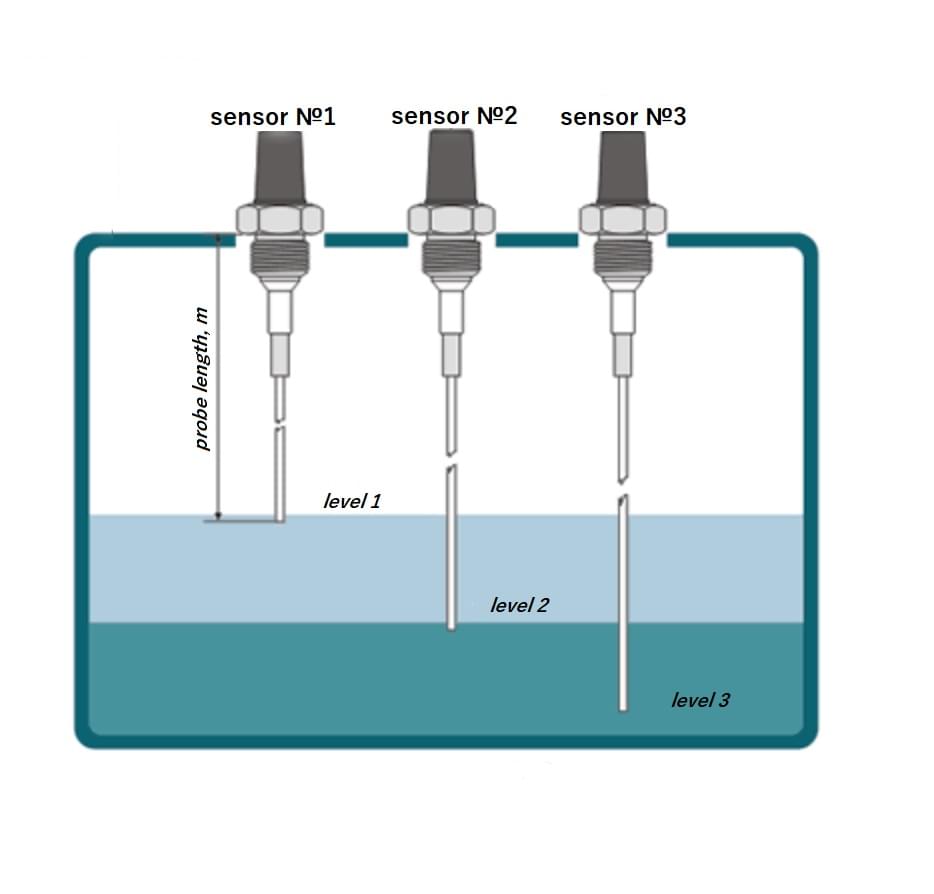

Functional principle of the RIZUR-300 sensors is based on the transformation of the electric resistance between the sensor's electrode and the tank's wall into a relay signal. Upon the immersion of the sensor's electrode into the controlled media, the resistance in the area between the electrode and the wall decreases, light-emitting diode lights up and a relay of the corresponding channel is activated. In case there's no medium, the resistance increases, light-emitting diode goes out, and the relay is deactivated.

Relay sensor consists of a secondary transducer and sensors (from 1 to 6 sensors, depending on the order). The secondary transducer consists of a housing and a lid made of cast aluminium with powder-polymer coating, an electronic unit, an outside ground screw, LED-lights, terminal block for plugging-in outer conductors and cables. Signal and power cables are plugged in through the cable glands.

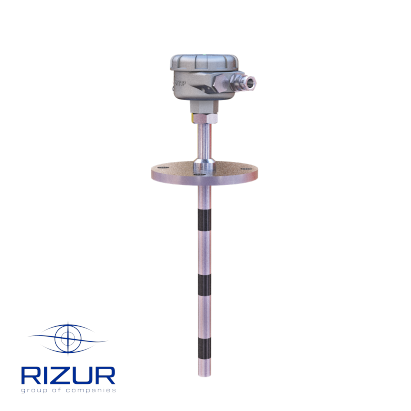

The sensor consists of a probe - rod or wire rope, a primary transducer, and a cap for sealing of the cable plugged into the terminal of the primary transducer.

Tank with the controlled media should be grounded and connected to the "GND" terminal of the transmission transducer. When installing the sensors to the tanks made of non-conductive materials (e.g. plastic), it's necessary to account for the presence of an additional electrode (e.g. metal plate) inside the tank that should be grounded and connected to the "GND" terminal of the secondary transducer.

The sensors should be located in such away that eliminates their short-circuiting between each other and between the additional electrode or the wall of a metal tank.

It's recommended not to use relay sensor for level control of liquids that generate non-conductive depositions (film) at the sensor's electrode. The connection between the secondary transducer and the sensor is done by a connecting link of any length in the object's limits with each cable's resistance up to 20Ohm.

| Medium operation temperature, °С | -100 ... +250 (silicone) -100 ... +450 (ceramic) |

| Process pressure, MPa | 2,5 |

| Probe material | stainless steel12Х18Н10Т |

| Primary transducer insulator material |

silicone

ceramic |

| Probe dimensions - |

rod: from 0,1 to 2,5 m (up to 5 m, on request) wire rope: from 1 to 22 m |

| Power supply, DC, V | 230 V (+10%/-15%), 50 Hz ± 2% |

| Explosion protection marking |

without explosion protection 1ExibIIBT4 |

| Installation position | any kind |

| Sensor material | 12Х18Н10Т (can be different on request) |

| Ingress protection | IP54 |

| Output signal | "dry" contact |

| Current consumption, no more than ... mA | 12 |

| Average service life, years | 7 years |

| Ambient temperature, °С | -60 ... +75 (-70 ... +75 with a soft enclosure) |

Dimensional specifications of the sensor

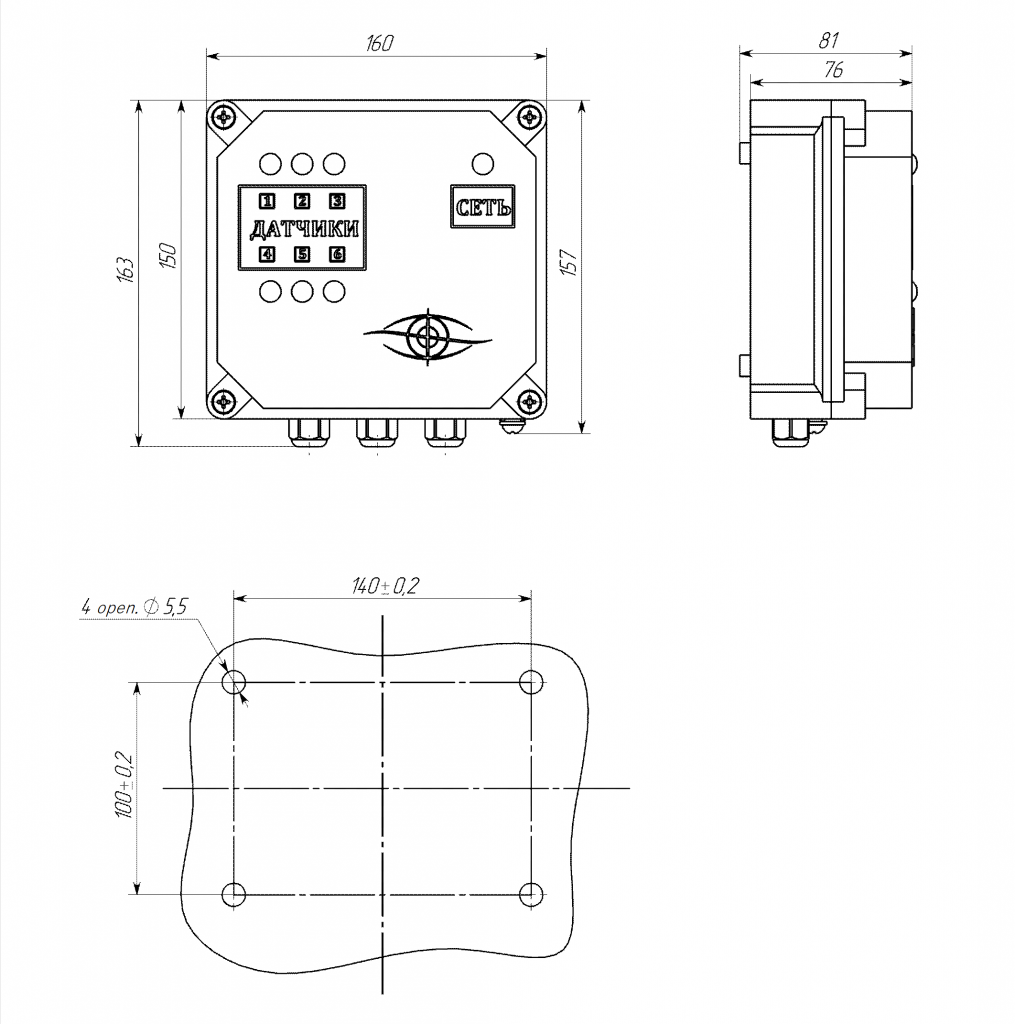

Dimensional specifications of the secondary transducer