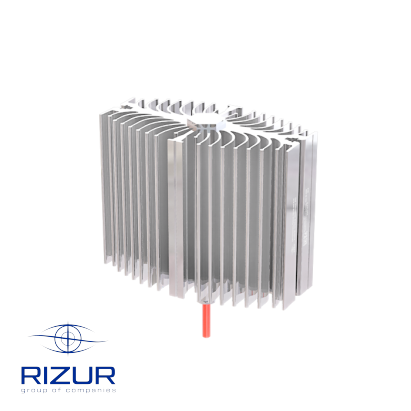

Heater RIZUR-TERM-B 230 V

Intended use and application area

Explosion-proof heaters RIZUR-TERM manufactured by OOO «NPO RIZUR» comply with TU-3442-001-12189681-2014 and, depending on configuration, comply with GOST R MEK 60079-0-2011, GOST IEC 60079-1- 2011 for electric equipment with explosion protection “explosion-proof enclosure(d)” and to GOST R MEK 60079-18-2012 for “compound sealing(m)”.Wide range of design variants that differ in the nominal power allows to choose a suitable version for heating either small spaces (soft enclosure, enclosure, safety shield, etc.) or big ones (block-boxes, warehouses, production departments, work-shops, gas distribution substation, boiler houses, compressor stations, etc.)

The design of RIZUR-TERM heater series is of high quality and thus ensures high-class protection against overheating and voltage surges; the heaters show steady performance and high reliability in field operating conditions. Their warranty time is 36 months, and the average operation time is over 15 years.

Design description

The heater consists of a section-shaped radiator made of aluminum alloy with powder-polymer coating. The shape is designed to optimize heating functionality. Inside the radiator, there is a high-endurance ceramic heating element on a basis of ceramic (PTC) semi-conductors that are sensitive to temperature changes. Electric resistance is in non-linear dependence with the heating temperature – when the temperature rises, the resistance of the ceramic heating element rises significantly, restricting the passing current and stopping the rise in temperature. Thanks to the self-regulating properties of the ceramic heating elements, RIZUR-TERM heaters on the basis of PTC-ceramics do not require stabilizing components or protection against surface overheating which means that the heater is fail-safe and has a longer service life.

The explosion protection is accomplished with a special explosion-proof housing. A special version of RIZUR-TERM heater is available – with the electric heating element and other elements in the metal housing sealed with a sealing compound. Protection from surface overheating is ensured by the area size of the outer surface, corresponding to the nominal power of heat generation, as well as (optional) by an added temperature sensor (analogue or digital, depending on specific versions) to switch off at a set maximum temperature. Thanks to the precise design and high-quality components, we can provide a 10-year warranty for heaters of this series.

The heaters are shipped with mounting components.

Fastening variants for RIZUR-TERM-B:

|

|

|

|

|

|

|

|

Advantages of RIZUR-TERM heaters on the basis of PTC-ceramics:

-

Self-regulation

-

Energy efficiency

-

High power density

-

Small size

-

Fail-safety

-

Absence of additional components that can result in higher risks of equipment failure, for example, the in-built thermostats

-

Long service life

Technical specifications

|

Installation area |

General industrial areas Explosion hazard zones V-1а and V-1g acc. to Electrical installation code (PUE), Ch. 7.3 |

|

|

Explosion-proof marking |

general purpose industrial version | |

| 1 Exd IIС (T3...T6) Gb X | ||

| 1 Exmb IIC (T3...T6) Gb X | ||

|

Heating element power |

300 ... 6000 W | |

|

Power supply voltage |

230 (±15%) V AC | |

|

Temperature on the heater’s surface |

In accordance with the temperature rating T4 - до +135 ºС T5 - до +100 ºС T6 - до +85 ºС |

|

| -30 … +110°C, an increment of1°С (with digital thermoregulators manufactured by RIZUR) | ||

|

Temperature maintained |

+10...+20°C (with thermoregulators on the base of a bimetallic thermostat) | |

| -40 … +110°C, an increment of 1°С with digital thermoregulators manufactured by OOO "NPO RIZUR" | ||

|

Ingress protection |

||

| IP67 acc. to GOST 14254-96 | ||

|

Insulation strength |

min. 1500 V | |

|

Insulation resistance |

min. 20 MОhm | |

|

Protection against electrical shock |

class 1 acc. to GOST 12.2.007.0 | |

|

Warranty period |

36 months | |

|

Average operation time |

over 15 years |

|