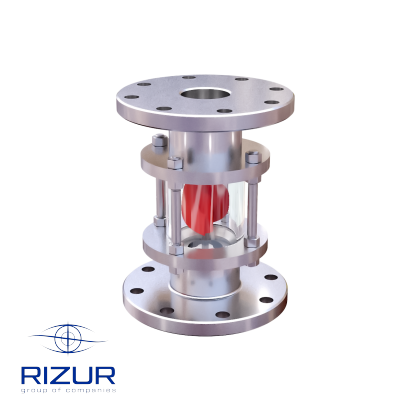

Sight flow indicator RIZUR-VIP-6

Sight flow indicators RIZUR-VIP-6 with cylinder housing and bolted flange insulation have thread (female or male) or flange process connection. Sight flow indicators RIZUR-VIP-6, depending on the design variants have impeller, balls or observation window only.

Sight flow indicators for liquid and gas RIZUR-VIP-6 have a cylinder housing and an observation window that allow to have an all-round panoramic view. These devices are used in pipelines of different purposes for media control and observation (flow presence/absence, direction of flow, colour; contamination level, presence/absence of additional agents).

Maximum operating pressure for the sight flow indicators RIZUR-VIP-6 is up 1,6 MPa.

Sight flow indicators RIZUR-VIP-6, depending on the design variant, are used with process temperature from -60°С to +250°С, and can be mounted horizontally or vertically.

Apart from pipelines with standard inside diameters (from 25 to 300 mm), NPO RIZUR can manufacture RIZUR-VIP-6 sight flow indicators of any diameter to suit all kinds of pipelines.

Sight flow indicators for liquid and gas RIZUR-VIP-6

The housing for sight flow indicators RIZUR-VIP-6 can be manufactured from the following materials:

-

stainless steel 03Х16Н15М3 (an analogue of AISI 316L),

-

stainless steel 08Х17Н13М2 (an analogue of AISI 316),

-

stainless steel 08Х18Н10 (an analogue of AISI 304),

-

brass,

-

carbon steel,

- non-standard materials (on request).

In order to achieve greater flow visibility, sight flow indicators RIZUR-VIP-6 are equipped with additional options – impeller (rotor) or balls, they can also have a scale or observation window backlighting. When the measured media passes through, the impeller rotates and the balls move around. This allows to observe low-speed flow and see measured media movement from a distance.

In these sight flow indicators, the insulator is made of graphite, ftoroplast, NBR, or Viton (fluorine rubber). These materials make the device completely sealed, the choice between them depends on the conditions of the technological process.

|

Housing |

Stainless steel 03Х16Н15М3 (an analogue of AISI 316L) |

|

Stainless steel 08Х17Н13М2 (an analogue of AISI 316 |

|

| Stainless steel 08Х18Н10 (an analogue of AISI 304) | |

|

Brass |

|

| Carbon steel | |

|

Other materials (on request) |

|

|

Observation window |

Tempered glass |

|

Borosilicate glass |

|

|

Insulation |

PTFE |

| NBR | |

|

Viton |

|

|

Graphite |

|

|

Inside nominal diameter |

1/8” or (1/2) – 2” and more (upon an agreement with the manufacturer) |

|

Process connection |

Flange |

| Thread | |

|

Maximum process temperature |

+250 °С (with PTFE insulation) |

|

Maximum operating temperature |

-60°С |

|

Maximum pressure |

1,6 MPa |

|

Assembly situation |

Any kind or (vertical/horizontal) |

|

Impeller/balls material |

PTFE (+250°С) |

|

Plastic (+100°С) |

|

|

Options |

Scale |

|

Observation window backlighting |

|

| Warranty period | 12 months |

| Average service life |

More than 25 years |

|

Customized version |

It's possible to manufacture any non-standard versions in accordance with the Customer's technical requirements |